The team at Industria Cartaria Tivoli turned to AFT to provide their new MaxEdge™ low consistency refiner and customized Finebar® MiniSegments™.

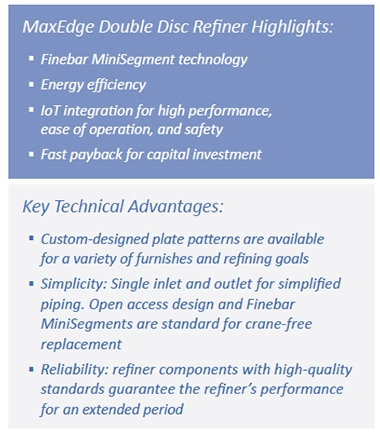

This compact and energyefficient refiner does the work of the traditionaltwo larger refiners.

“Soon after installation of the MaxEdge refiner, energy usage dropped by 40% and steam savings were achieved. Also critical to success are enhancements to our fiber—not over or under-refining. There is an art to optimizing the properties you seek when you make tissue and toweling. The MaxEdge refiner equipped with Finebar MiniSegments delivers precisely that,” says Tomas Saliola, Maintenance and Operation Manager at Industria Cartaria Tivoli.

The team at Tivoli had very specific objectives for strength and absorbency, which were achievable because of the AFT MiniSegment design.

“AFT understands the nuances of tissue making, which is an advantage for us,” comments Mauro Caponi, Shift Leader at Industria Cartaria Tivoli. “The baseline property for successful tissue making is tensile strength – both dry and wet. Building on strength, softness and absorbency can be enhanced.

Refining with precision is critical to meeting the specifications needed for a wide range of end-use products and customers. The support from AFT to achieve greater control of the process is a big plus. Also, IoT integration gives us better refiner performance, ease of operation, and assures safety too.”

What else to achieve results?

Emidio Lo Monaco, AFT representative and CEO of Techno Paper Srl, emphasizes the importance of a refiner. “Flow control, energy requirements, sizing of valves, pumps, recirculation – many tissue systems fail because of poor installation.

Not taking care of correct recirculation is a common problem. Each grade has its unique needs. Proper flow through the refiner is critical.”

Refining finesse

AFT Application Manager Francesco Pantanella notes that energy must be applied in a particular way. “For tissue making, the importance of refining is far more than seems apparent. It’s all about finessing the fiber. There’s never a straightforward formula. It’s always unique to the application. Finebar offers a wide range of plate pattern options to achieve this.”

Says Caponi, “Bulk matters, especially for toilet tissue. Of course, runnability has to be at a steady, high-performance level. MaxEdge and Finebar technologies allow the team here to meet our targets consistently.”

Safety and ease of handling

Finebar MiniSegments are the ideal complement to the MaxEdge refiner – each segment light enough to hold in one hand. They can be easily changed, depending on fiber refining needs. Because they are long-lasting, wear life is not an issue.

Mechanical packing: assures no leaks

Gland packing is eliminated in favor of a mechanical seal. This means less scheduled and unscheduled maintenance work is required for the refiner. No sudden fiber loss happens, as the mechanical seal method needs no supervision.

Notes Saliola, “The mechanical seal is a significant advantage for the MaxEdge refiner. Otherwise, the classic leaks from poor gland packing are a frequent headache.”

Benefits outside the scope

As Saliola puts it, “AFT’s support in optimizing the DCS system not only improved the refining line, it was also beneficial to our overall operations. We can run the machine at full Yankee speed.”

Rapid returns

With a payback of only two months or less, based on energy savings alone, the decision to order a second refiner for their board machine was straightforward.

According to Olli-Pekka Riippa, AFT Product Manager – Refiners and Deflakers, “We are proud that Industria Cartaria Tivoli has purchased a second MaxEdge refiner for their board machine. We are all smiling about this rather small ‘workhorse’ refiner that has precise performance with low energy usage. In addition to tissue manufacturing, evidence of the success of MaxEdge and Finebar technologies can be seen worldwide for a wide range of grades.”

Emidio Lo Monaco (left), and Francesco Pantanella of AFT. After installation of the MaxEdge™ refiner and customized Finebar® MiniSegments™, energy consumption at the mill was dramatically reduced.

Emidio Lo Monaco (left), and Francesco Pantanella of AFT. After installation of the MaxEdge™ refiner and customized Finebar® MiniSegments™, energy consumption at the mill was dramatically reduced.

AFT is a global supplier specialized in screening, refining, stock preparation, and paper machine approach flow systems. With over a century of experience, AFT offers solutions tailored to the customer’s furnish, mill process, and end-product being produced in order to optimize the return on investment.

For more on AFT technologies, visit aft-global.com