Blogs - Insights from Pulp and Paper Industry Experts

In The Spotlight

FPAC Sees Biomass Investment Tax Credits and Regulatory Efficiency Commitments as Key to Improving Competitiveness for the Long-Term

Feature Articles

Top Stories

I was first introduced to rice paper as a child when my mother baked almond macaroons.

I first came across the concept of a digital twin when I learned, many years ago, how to use CadSim software,...

Over 140 countries have adopted net-zero pledges by 2050.

FPInnovations will present a joint webinar with QWEB and Canada Wood on market diversification, ...

Research Information Sharing and Feedback (RISF) webinars are offered to FPInnovations’ members ...

The federal government has announced the launch of the Wildfire Resilience Consortium of Canada (WRCC)...

FPAC Sees Biomass Investment Tax Credits and Regulatory Efficiency Commitments as Key to Improving Competitiveness for the Long-Term

Canada’s Forest Sector Seeks Clear Signals in Budget 2025 to Set Stage for Recovery and Growth

European Union (EU) Commission Proposal on EUDR misses the mark

FSC has launched a public consultation on the revision of Advice Note 20-007-23: Maximum hectare threshold for ‘very limited portion.’

The Guidance for Demonstrating Ecosystem Services Impacts (FSC-GUI-30-006a V2-0 - also known as Ecosystem Services Guidance) has been published.

Join FSC US and FSC Canada on September 18 for an introductory webinar on how FSC can benefit the beauty and wellness industries.

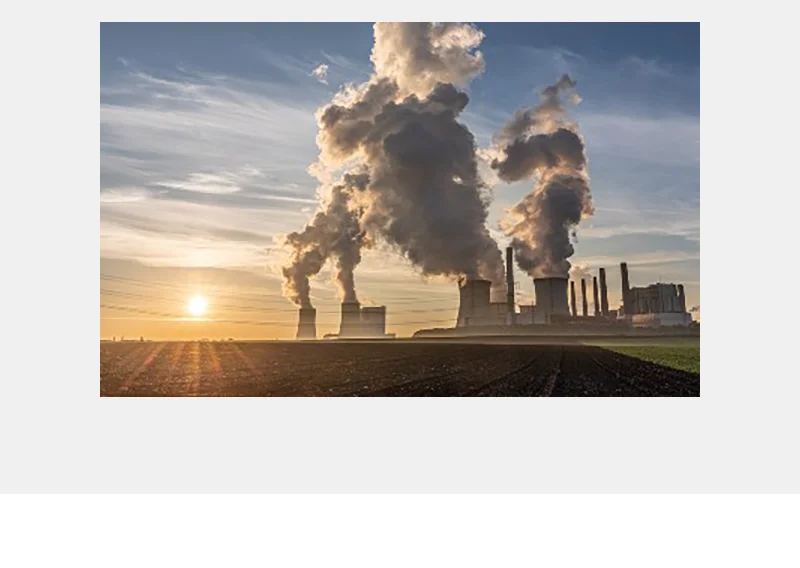

In an increasingly industrialised and interconnected world, environmental issues are becoming more and more important as the years go by.

Transforming textile waste into paper products: A Quebec innovation at the forefront of the circular economy

The current transformation of the paper industry involves the creation of new products.

Recycling takeaway coffee cups has long been a challenge. Most are made from paperboard lined with a thin layer of plastic or polyethylene to resist liquids, ...

After nearly three years of negotiations, the sixth round of talks on a global plastics treaty concluded on August 15 in Switzerland.

The Ontario government recently proposed amendments to the province’s Blue Box Regulation, triggering swift reactions from stakeholders.

As the global pulp and paper sector moves through 2025, one thing has become clear: resilience isn’t just a buzzword - it’s a survival strategy.

Since the onset of the Trump-era trade wars, tariffs and trade tensions have become a defining characteristic of US economic policy...

UPM will end paper production at Kaukas (Finland) and Ettringen (Germany) paper mills, ...