Pulp and Paper Mill and Technologies

In the Spotlight

Voith and Wuzhou Special Paper have successfully commissioned the new PM 21 specialty paper machine in Hanchuan, Hubei Province.

Feature Articles

Top Stories

Enhancing the Longevity of Paper Machine Reel Spools through Phased-Array Ultrasonic Testing

In the pulp and paper industry, tank cleaning is often treated as a routine maintenance task—necessary but inefficient.

In the pulp and paper industry, energy consumption and efficiency are not just buzzwords; they are the linchpins of sustainable and profitable operations.

In modern papermaking, one of the most effective methods for removing water from the sheet is through the utilization of steam’s latent heat of vaporization.

A corrugated packaging plant in the U.S. Midwest turned to Kadant Johnson to resolve a persistent syphon clearance issue affecting heat transfer and board quality.

Case Study: For months, the white liquor clarifier was a source of constant frustration, its behavior a daily mystery.

The pulp and paper industry is constantly evolving, driven by the need to optimize processes and uphold high-quality standards.

ABB has introduced ABB Ability™ Plant Optimizer for Pulp Mills, a dynamic software solution ...

The pulp and paper industry has always been capital-intensive, driven by large-scale equipment, complex processes, and global supply chains.

Another milestone for the digital future at PKV: digitalization specialist T.CON supports the manufacturer of corrugated papers and cardboard with successful SAP S/4HANA implementation

Eagerly awaited by ERP enthusiasts in the paper industry and beyond: Release 25.05. of SAP Digital Manufacturing (DM), ...

Fedrigoni has entered a multi-year strategic partnership with Palantir Technologies to accelerate its digital transformation using artificial intelligence.

Metsä Fibre and Rauman Energia have signed an agreement to channel surplus heat from the Rauma pulp mill ...

UPM has taken another step in its decarbonisation strategy with a new Power Purchase Agreement (PPA) for wind energy in Germany.

Ahlstrom’s Thilmany plant in Kaukauna, Wisconsin, has been recognized with the 2025 Energy Efficiency Excellence Award by Focus on Energy.

In 2024, Södra reinforced its position as a major producer of biomass-based green electricity, ...

Kruger Energy has announced plans to double the installed capacity of its Zacapa Solar facility in Rio Hondo, Guatemala.

Kimberly-Clark has announced that its tissue manufacturing facility in Koblenz, Germany, is set to transition to 100% renewable energy by 2029.

Training your maintenance and operations team at the right time can be crucial to ensure the smooth and efficient operation of your business.

It all starts with the nozzle. The nozzles on the showering systems in the Pulp and Paper industry are just like any other wear components.

In manufacturing, the variable area flow meter, or rotameter, stands out for its simplicity, affordability, and versatility.

Warren DeBay, Maintenance Reliability Engineer at Ahlstrom’s Rhinelander plant, was honored with the prestigious "Innovator of the Year Award" by KCF Technologies during their Manufacturing the Future event.

Voith and Wuzhou Special Paper have successfully commissioned the new PM 21 specialty paper machine in Hanchuan, Hubei Province.

The paper industry, long recognized as an energy-intensive sector, is now at a crucial turning point.

Many tissue mills face the ongoing challenge of sustaining high production standards while navigating workforce changes ...

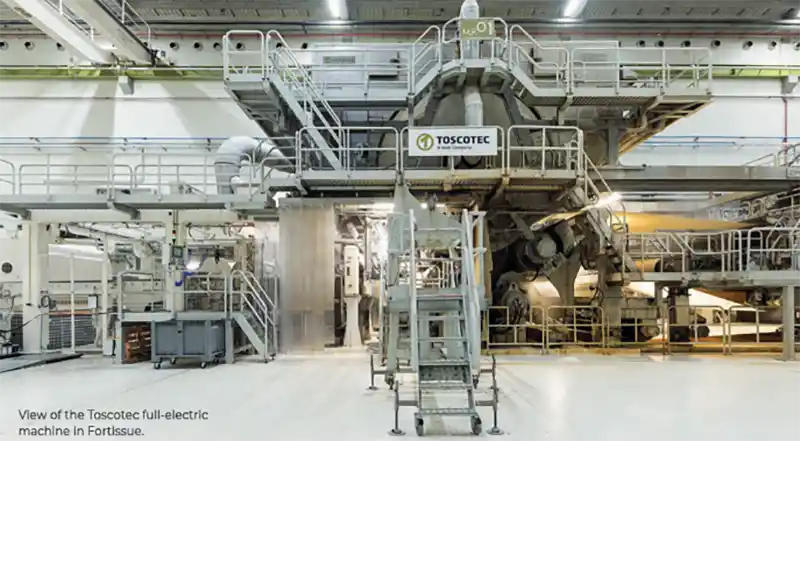

Toscotec will supply a complete rebuild of PM3’s drying section to Papeterie le Bourray mill in Saint-Mars-la-Brière, France.

In papermaking, the dryer section is where efficiency, profitability, and product quality are ultimately determined.

Voith introduces new CellPress roll cover for chemically demanding applications in pulp production

The sawmilling division of J.D. Irving, Limited (JDI) set a safety record in September, achieving the lowest incident rates in its history.

At Mondi’s Dynäs mill in Sweden, safety is a core value that extends beyond policy into the very culture of the workplace.

Georgia-Pacific's gypsum facility in Fletcher, Oklahoma, is developing an innovative AI-powered app to bolster its workplace safety measures.

Mercer Peace River has reached an impressive safety milestone by achieving a TRIR of 0.0 over a 12-month period.

At GP Cellulose, the safety and well-being of our employees and communities is our first priority.

Kruger reaffirmed its commitment to workplace safety by celebrating the achievements of its intervention brigade at the Wayagamack Mill in Trois-Rivières.

Smurfit Westrock is highlighting the growing importance of sustainable supply chain innovation as a driver of both business performance and environmental progress.

The paper and packaging industry is facing major challenges: raw material prices, energy costs, environmental regulations and ...

In a rapidly changing job market, leadership development and a strong understanding of internal operations have become essential.

Bracell is expanding its role in the pulp sector through projects that integrate renewable energy, ...

Metsä Fibre recently published an article outlining how the company ensures the purity and safety of its fresh fibre pulp, ...

Huhtamaki is celebrating the successful integration of its new egg packaging facility in Zellwood, Florida, ...