Like many industries, the global pulp and paper sector is focusing on developing innovations to address the urgent requirement for decarbonization to ensure a sustainable future.

The tissue and towel industry has long required high levels of energy consumption, derived primarily from fossil fuels to produce heat. Given the substantial carbon emissions associated with this and the importance for brands to maintain their environmental commitments, manufacturers must decarbonize. Doing so means meeting consumer demand for more environmentally responsible products while complying with governmental regulations to address climate change.

An example of one tissue manufacturer working towards decarbonization is Kimberly-Clark Australia (KCA). The company recently announced its plan to use green hydrogen in its operations at its Millicent mill, in partnership with technology development company entX.

The Green Hydrogen Transition

entX's LCH2 Project is set to transform the energy source used in tissue manufacturing at Kimberly-Clark's Millicent mill. The collaboration aims to revolutionize KCA's tissue manufacturing processes by substituting natural gas with green hydrogen.

The project will unfold in two stages. The initial phase will introduce a 20% green hydrogen blend into the mill's existing natural gas feed by 2027. By 2029, the project aims for a complete transition, moving from natural gas to 100% green hydrogen.

This strategic shift propels KCA towards its carbon reduction targets. It also serves as a lighthouse project for sustainable manufacturing practices in Australia and beyond. Such a move marks a significant step in aligning industry practices with environmental sustainability goals.

What This Transition Would Mean

When it comes to mills converting to green hydrogen, several questions need to be answered.

- How much green hydrogen would be needed?

- How much would converting the mill to green hydrogen cost?

- What would be the cost difference?

With FisherSolve at their disposal, mills can confidently address these inquiries. Our advanced tool allows users to intricately model the cost-of-production for every mill, pulp line, and machine. Leveraging FisherSolve's comprehensive asset and raw material database provides valuable insights into operational costs, enhancing their understanding of real-world expenses within the industry.

Let's use KCA as an example.

As per FisherSolve data, the Millicent mill has an annual heat requirement of 1.5 million GJ, with gas priced at $6.32 per GJ. On the other hand, Prima CarbonZero (ResourceWise’s low-carbon fuels and feedstocks pricing platform) reveals that green hydrogen costs $7 per kg, translating to an additional $50 per GJ for the transition.

Using FisherSolve, we can also analyze the carbon output of the Millicent mill post-green hydrogen integration. With a 10% energy displacement resulting in 7,000 tons of carbon savings, the cost comes to about $1,500 per ton of carbon eliminated. The critical question arising from this data is whether consumers are willing to bear this cost for sustainability.

Reducing Carbon Footprint with ResourceWise's Toolset

Decarbonization is not just an environmental necessity. It's increasingly becoming a competitive differentiator as governments worldwide roll out initiatives to combat climate change. As consumers increasingly lean towards brands that demonstrate genuine commitment to sustainability, this is becoming increasingly important.

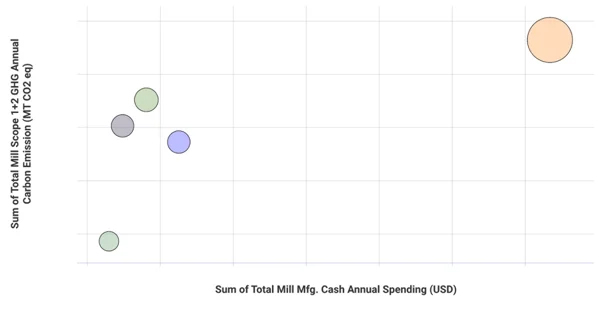

The image below analyzes carbon emissions and cash costs for tissue and towel mills in Australia. As we can see, the mill emitting the highest carbon emissions also incurs the highest annual costs, while the mill with the lowest carbon footprint boasts the lowest annual expenses. This emphasizes the critical importance of managing and reducing carbon emissions effectively.

Carbon Emissions vs Cash Costs: Australian Tissue and Towel Mills

Source: FisherSolve

Source: FisherSolve

Utilizing the comprehensive data and analysis capabilities of ResourceWise's market intelligence platforms, companies gain invaluable insights into the environmental impact of shifting from fossil fuel to green hydrogen in tissue manufacturing.

FisherSolve helps dissect the intricate details of energy consumption, production efficiency, and carbon footprint metrics across the industry. By leveraging this platform, industry players can visualize the tangible benefits of integrating green hydrogen into their operations. Benefits include anything from significantly lowering greenhouse gas emissions to enhancing overall sustainability profiles.

Beyond the clear environmental benefits, the transition to green hydrogen offers an economic advantage by mitigating long-term risks associated with fossil fuel prices and availability. ResourceWise’s Carbon Mitigator report further extends these insights, providing an in-depth analysis of green hydrogen pricing trends and forecasts. This critical data equips decision-makers with the information needed to execute strategic transitions effectively, ensuring both economic and environmental sustainability.

Data-Driven Decisions for Decarbonization

The move by Kimberly-Clark towards green hydrogen represents a crucial step in the broader industry's path to sustainable manufacturing. It underscores the importance of reliable, data-driven resources like FisherSolve and the Carbon Mitigator report in facilitating informed decisions that align with both business objectives and environmental commitments.

For industry professionals and tissue producers, these tools are indispensable in navigating the complexities of decarbonization, offering a clear roadmap for a sustainable and profitable future.