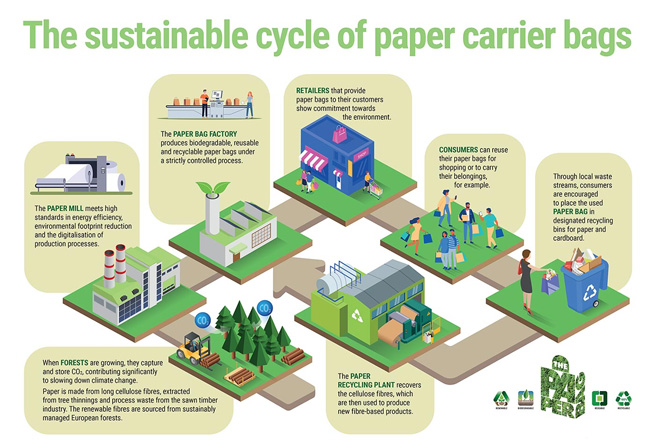

Stockholm, 20 February 2024. Less raw material, less waste, fewer emissions – the circular economy is at the top of the agenda. Choosing fibre-based packaging such as paper carrier bags is one piece of the puzzle that retailers and brand owners can complete to take the next step in contributing to the bio-based circular economy. Paper carrier bags are a welcome resource in the paper recycling mix. A member of the initiative “The Paper Bag” explains how paper carrier bags are recycled into new fibre-based products. An infographic shows the cycle of paper carrier bags.

A study has found that fibre-based packaging can be recycled more than 25 times1 . It concluded that the number of possible recycling cycles is limited mainly due to losses that occur during the cleaning of the fibre material and the collection rate. In Europe, the recycling rate for paper and cardboard packaging is already very high at 82.5% in 20212 . The 4evergreen alliance set the goal to reach 90% for fibre-based packaging by 20303 . “Paper carrier bags are a valuable part of the paper recycling mix,” knows Matías Cowper Coles, Business Development Manager at the Spanish paper producer and paper recycler Alier. Alier is one of the members of the initiative “The Paper Bag” that recycles paper carrier bags and produces new fibre-based products from the fibres – among them paper carrier bags. But how does this work in practice?

Paper collection

When a paper carrier bag is no longer good for another reuse, it should be placed in the paper and cardboard recycling bin. In Europe, different paper grades are collected in the same container. After being picked up by the designated facilities, the paper is separated into different qualities. This is important because for some products, high-quality fibres must be used. Paper carrier bags, as other kraft paper products, can be sorted into different qualities, depending on the demand and the quality. Usually, they are mixed together with OCC – old corrugated cardboard.

Alier produces 100% recycled paper for different end uses. Copyright: Alier

Alier produces 100% recycled paper for different end uses. Copyright: Alier

Recycling paper carrier bags

When the raw material arrives at the paper factory, samples of the material are tested to classify them according to different parameters that are important for the papermaking process and the qualities that will be produced at the mill. “For each of our paper grades, we need a special material mix. The stronger recycled kraft paper we want to produce, the longer the fibres have to be in the mix,” explains Cowper Coles. “The kraft paper for paper carrier bags is one example where we use material with long, strong fibres.” For the recycling process, the selected paper mix is put into a pulper. The resulting pulp is filtered several times and cleaned of impurities. It is then collected in silos and stocked before it enters the paper machine, where it is manufactured into new paper that can be used in carrier bags, paper sacks, test liners or fluting.

The paper bag fibre cycle

The Spanish organisation La Bolsa De Papel has produced an infographic that demonstrates the fibre cycle for paper carrier bags – from the sourcing of the raw materials, the production of the paper and the paper bags via the distribution at retail sites, the use and reuse from consumers to the collection and the recycling process. “Reusing and recycling paper carrier bags replaces new raw materials. This saves natural resources and reduces greenhouse gas emissions since the CO2 will keep stored in the paper products for a longer period,” explains Elin Gordon, Secretary General of CEPI Eurokraft. “Therefore, we want to encourage retailers to support the circular economy. They can do so by offering paper carrier bags to their customers and motivating them to reuse their bags for as long as possible before placing them in the recycling bins for paper and cardboard to recycle the fibres.”

The Paper Bag

“The Paper Bag” platform was founded in 2017 by the leading European kraft paper manufacturers and producers of paper bags. They dedicate themselves to promoting the advantages of paper packaging. “The Paper Bag” is steered by the organisations CEPI Eurokraft and EUROSAC. thepaperbag.org

CEPI Eurokraft is the European Association for Producers of Sack Kraft Paper for the Paper Sack Industry and Kraft Paper for the Packaging Industry. It has ten member companies representing a volume of 3.0 million tonnes of paper produced in eleven countries. cepi-eurokraft.org

EUROSAC is the European Federation of Multiwall Paper Sack Manufacturers. The federation represents over 80% of European paper sack manufacturers. Its members operate in 20 different countries. They produce some 5 billion paper sacks per year, representing 630,000 tonnes of paper converted in 55 plants. Sack manufacturers from all continents and bag manufacturers also contribute to the federation as corresponding members, and more than 30 suppliers (paper, film, machine or glue manufacturers) are registered as associate members. www.eurosac.org

Source: The Paper Bag