The primary function of a wire- and press section in a paper machine is to remove water from the paper sheet.

In order to understand the effectiveness of individual elements (such as save-all pans and suction boxes) of a wire- and press section, the dewatering rate must be measured. Without this, critical air flow (i.e. vacuum level) review and consequent optimization cannot be successfully carried out. Water removed from the paper sheet contains air, and is often subject to foaming. Traditional magnetic liquid flow meters demand a homogenous flow and will not be able to provide accurate data. Runtech’s Ecoflow dewatering meters are designed to measure water flow across a mechanical restriction and are not sensitive to entrained air or foaming. These devices are used both under vacuum (in a separator drop leg) and in atmospheric conditions.

EcoFlow dewatering measurement system optimizes dewatering and vacuum levels in the forming and press sections. EcoFlow provides maximized sheet dryness after the press section, improved machine runnability and maximum energy efficiency, while providing papermakers with accurate real-time feedback about the dewatering performance along the paper machine.

EcoFlows are designed to work with doctoring to gain maximum energy efficiency. Dewatering and doctoring are not only related to energy consumption, but they also have big effect on whole machine runnability, efficiency and profitability, as well as the paper profiles. A well-designed and operated dewatering and doctoring system is one of the key issues to a well-performing and energy-efficient machine. A lot a paper machines have them but they are not effective and do not have the adjustability that is needed to optimize them effectively. In order to get the full benefits from increased dewatering, an online dewatering monitoring, efficient water discharge and rewet prevention are necessary. Runtech Ecoflow, save-alls and double doctors can perfectly match these needs.

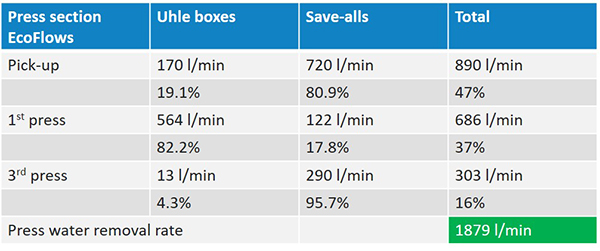

A typical EcoFlow system in a three-nip press section. Based on the data, it is very easy to compare different felts and adjust water removal.

Runtech is one of the leading suppliers for the improved dewatering and doctoring solutions for all kinds of pulp, paper, board and tissue machines. In many cases, Runtech’s solutions have led to a 1-3% increase in dryness after the press section, which saves considerable amount of energy in the dryer section (4-12% less steam).

Over 600 paper machines are equipped with EcoFlow. At Smurfit Kappa Ania PM2 & PM3, Italy, dewatering and doctoring optimization resulted in total energy savings of 9 GWh/year in the vacuum system.

Runtech Systems is a global provider of engineered systems tailored to the pulp and paper industries. Runtech works with customers to better understand and control their operational conditions to maximize efficiency and cost effectiveness. www.runtechsystems.com