From log to product: 100% recycling

Every year, Mercer Torgau processes 1.1 million cubic meters of wood into high-quality products. The raw material comes from sustainably managed forests and is used 100% in line with the green circular economy.

Mercer Torgau implements a concept that is unique in the European packaging industry: the use of 100% renewable wood, from the bark to the last chip. The use is based on ecological and economic aspects in a unique value chain: bark is used to generate heat and green energy, while sawdust and wood chips from the company’s own sawmills are used to produce pallets and high-quality pellets and briquettes.

3D measurement systems as the basis for optimal use

The optimal use of the raw material begins as soon as it arrives at the plant: After being debarked, all logs are recorded using modern, certified 3D measurement methods and measured in accordance with the currently valid guidelines. The data obtained forms the basis for further processing in the sawmill. In addition to the geometric data, attention is also paid to the quality of the logs. The thicker logs are run through an X-ray scanner directly before cutting, which determines the quality parameters and the type of wood in addition to the geometric data of the wood, so that the log can be cut optimally with the best yield.

Use of the wood chips for pallet blocks, briquettes and pellets

The logs are used to produce high-quality pallets, sawn timber, garden and milling products as well as biofuels. The sawdust and wood chips produced when cutting the boards also play an important role: they are processed into pallet blocks and high-quality pellets and briquettes. This makes optimum use of wood as a resource.

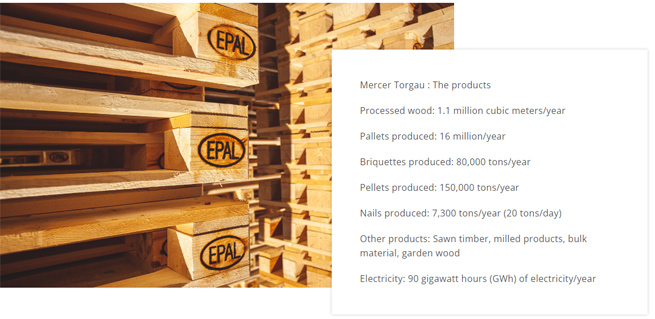

At the same time, this concept allows for unique self-sufficient production, as both blocks and boards are produced on site and joined together in pallet production. Pallet production use up to 20 tons of nails per day, produced at Mercer Torgau, and are certified by European Pallet Association (EPA)L. From these, the boards and blocks, the typical EPAL pallets, chemical pallets and also special pallets are produced on the 9 fully automatic pallet lines, depending on customer requirements.

Energy from Torgau’s own bio-cogeneration plants

The up-to-17-million pallets per year are dried in nine drying chambers and in one of the largest channel dryers in Europe, which is located on the factory premises.

The energy for drying comes 100% from renewable energy produced in the company’s own power plants. The power plants are fed with renewable bioproducts materials in compliance with the Renewable Energy Sources Act. At Mercer Torgau, this is the bark of the tree trunks or residual forest wood.

The electricity produced is theoretically enough to supply around 30,000 households with CO2-neutral, green electricity. The company feeds surplus energy into the public power grid.

“The integrated value chain that we have implemented at Mercer Torgau is unique in several respects,” says Frank Badeda. “Firstly, it allows us to work very self-sufficiently, apart from purchasing renewable raw materials. Secondly, the optimal use of biomaterials is practiced here in a sustainable way.”

Source: Mercer International