Jade Road is a haul road that intersects Highway 105 about 12 km north of Ear Falls, Ontario. Built and used over 60 years ago, the road was later de-activated.

Plans to put it back into service for log hauling starting in spring 2023 meant that it needed to be re-surfaced and drainage re-established.

Last year, FPInnovations specialists were asked to develop and budget cost-efficient road reinforcement options with geosynthetics for the Jade Road. This project aimed to upgrade the road for today’s heavy haul trucks by adding a thick layer of pitrun aggregate on top of the old road surface. FPInnovations road researchers Francis Bober (formerly with FPInnovations), Papa-Masseck Thiam, and Allan Bradley were also asked to monitor construction activities to ensure that the geotextiles were installed using best practices and per the road designs. Meek Forestry Service performed the upgrade and Barrens Northern Transportation loaded and hauled the locally sourced pitrun gravel.

Description of work

The start of the Jade Road passes through a weak clay deposit that loses much of its strength when saturated and drains very slowly (i.e., it can stay weak for a long time). FPInnovations selected geosynthetics for the project that would be both economic and effective at reinforcing the weak clay subgrade. The design objectives were:

- To create a bulletproof road that would survive very weak wet soil conditions and heavy truck traffic; and

- To develop a road comparable in strength to a deep gravel layer (the current approach to wet sections).

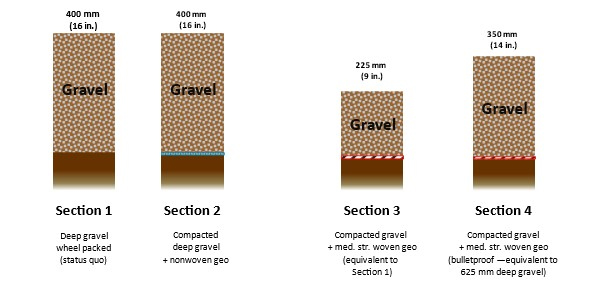

Four road designs were trialed on the Jade Road:

- The first trial section, which was 450 m long, was a conventional solution featuring about 400 mm of pitrun material that was spread, shaped, and then wheel packed by the gravel truck traffic. Apart from requiring a lot of gravel this road design has been known to fail under very weak subgrade conditions. Modeling showed that the gravel layer would need to be 625 mm thick to provide a “bulletproof” road that never fails under wet road conditions.

- The second trial section was 410 m long and was an improved version of the 400 mm-thick section. FPInnovations improved the deep gravel design by underlaying it with non-woven geotextile to act as a separator layer and having a vibrating drum roller compact the gravel in lifts.

- The third trial section was 1080 m long and featured a gravel layer 225 mm thick, reinforced with moderate strength woven geotextile, and compacted in lifts. This section was comparable in strength to the first, deep gravel, section but required 44% less aggregate.

- The fourth section was 360 m long and was intended to provide a “bulletproof” solution and it had 350mm of gravel, reinforced with moderate strength woven geotextile, and compacted in lifts.

Estimated construction costs for these trial sections ranged from $38,000 to $63,000 per kilometre (see details in table below). According to John Meek, owner of Meek Forestry Service, spending a bit more to construct roads well can easily pay off if they provide reliable access throughout wet weather periods and spring thaw. Although the construction cost for section 1 is lower than for the reinforced sections, a life cycle cost analysis (LCCA) may show that it is actually a more expensive option.

While on site, Allan Bradley and Francis Bober worked with HTTV of Kenora, ON to prepare a video showing the project highlights:

2023 project follow-up

The trial sections were put to the test during the spring of 2023. This summer, FPInnovations researchers will return to the Jade Road to learn about the performance of the trial sections during hauling, gather details about construction and maintenance costs, and make a determination about whether the geotextile-reinforced sections were an effective and economic alternative to a deep gravel layer.

For more information about the project, please contact Allan Bradley at

Source: FPInnovations