Planar microwave moisture measurement, since its inception in 2000, continues to develop sophisticated instrumentation tools which greatly expand the utility of the technology into an ever-expanding range of papermaking applications.

A new generation of instruments have now been developed allowing for an increased accuracy in lower water content levels permitting reliable data collection in TAD applications. These units use less radiation than a cell phone produces, is safe to the touch and require no government certifications of some sort.

Other technologies either rely upon nuclear radiation from so-called “backscatter” gages, are limited in penetration or operate in lower frequency spectrums which causes them to lack in reliability.

Currently, process improvements on TAD machines are often measured by having operators collect hand samples while the sheet is sent to the pulper. This poses some degree of risk to both the operator and machinery. Considering the sensor reads constantly in a fixed location and outputs its results to the DCS, the process shifts can be seen in real time thus, eliminating safety risks and as well as the delay between the time the sample is collected and the lab results.

This paper takes a brief look at the basics of how this technology works vs. older forms of water measurement. There is a brief explanation of this new technology being offered to the TAD market. This includes the difference between planar (digital) and resonance chamber (analog) signals produced for analysis.

The selected case study presents the collected moisture content collected by the instrument over a range of basis weights. The results show good correlation coefficients for all basis weights while identifying even minor changes to the process.

Technology:

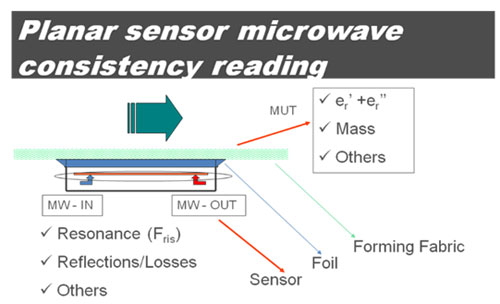

Figure 1 demonstrates that a fabric or a fabric/sheet passing over the head will cause a change in the flux of the microwave field set up between the incoming source (antenna) and the receiver. That microwaves cause resonance in water molecules above the sensor, means that all the sensors perceive is the water itself, not the fiber, the fabric, or the surrounding machinery.

Figure 1. New planar sensor operates without a resonance chamber.

Figure 1. New planar sensor operates without a resonance chamber.

The Instrument:

The SmartScan can be mounted anywhere that the roughly 10 X 12 cm sensor head can fit. Since the instrument does not see the machine framing in its measurements, not only can tight fitting spaces can be accommodated between machine elements, but this instrument can be mounted to measure while the sheet is supported by a fabric or roll.

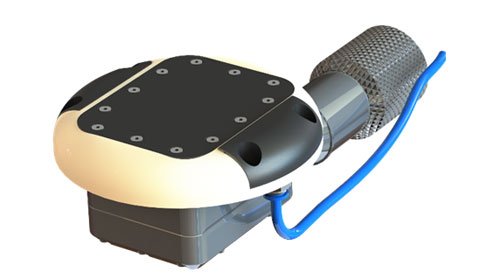

The instrument shown in Figure 2 measures lower moisture values with accuracy of +/- 1 gsm. This allows for applications that need to measure sheet consistency with accuracy greater than +/- 10 gsm such as TAD or Transfer fabrics.

In the past, only heavier weight sheets could be measured because the sensor head had to be in contact with the sheet, and only special cases could tolerate this without the risk of sheet breaks. Our “new generation” technology now allows the sheet to be as far as several millimeters away from the sensor head, and still obtain a high accuracy and precision (+/- 1gsm water content).

Figure 2. A new generation sensor that can measure sheet consistency with accuracy of +/- 1 gsm

Figure 2. A new generation sensor that can measure sheet consistency with accuracy of +/- 1 gsm

CASE STUDY

For The last 15+ years, the greatest expansion in the paper industry has been the TAD segment. The complexity of these machines frequently present challenges to the installation of instrumentation, but recent work with paper companies has shown that microwave moisture measurement is possible and provides accurate sheet moisture levels without the need for grab samples. Obtaining grab samples can be a safety risk, and the lab-measured consistency is often called into question.

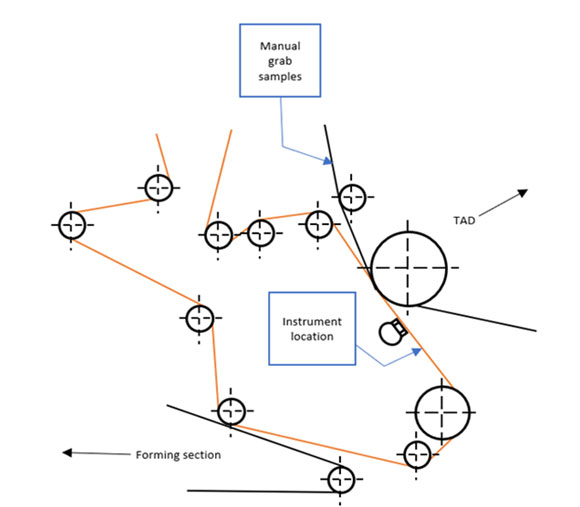

Figure 3 is a simplified drawing of where the instrument was located vs. where the grab samples were obtained. The vacuum box shown on the drawing was not in use for the purpose of these trials.

Figure 3 shows the location of the places where hand samples and where the instrument are placed.

Figure 3 shows the location of the places where hand samples and where the instrument are placed.

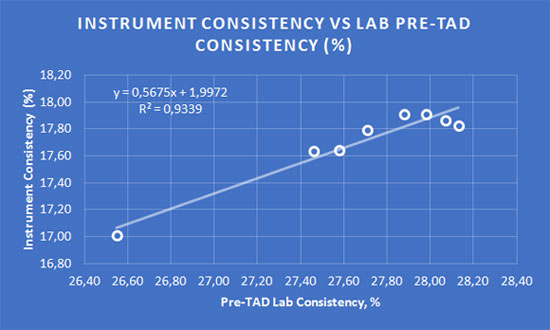

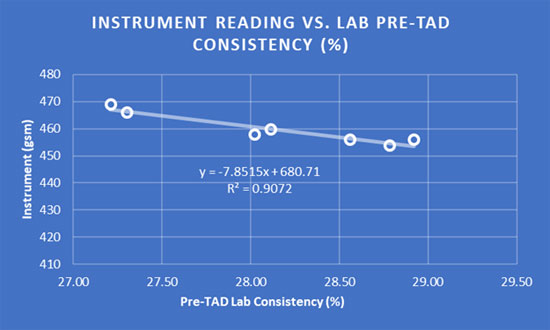

In our first round of trials data was gathered that compared the microwave instrument readings to grab sample lab readings while various process variables were changed, designed in improve and/or reduce water removal performance. These results are shown in Figure 4.

Figure 4 shows a good level of R-squared (coefficient of determination).

Figure 4 shows a good level of R-squared (coefficient of determination).

The R-squared value indicates how well the data conforms to a linear regression. The 0.93 level shows that the data have a good correlation to a straight line, but as obvious on the graph, the absolute values don’t agree.

We then looked at the data comparing the absolute moisture content as measured by the instrument, to the lab measured consistencies. Those results are shown in Figure 5 and shows a good coefficient of determination at 0.91.

Figure 5 shows that instrument-gathered sheet water content is a good correlation with lab-measured data.

Figure 5 shows that instrument-gathered sheet water content is a good correlation with lab-measured data.

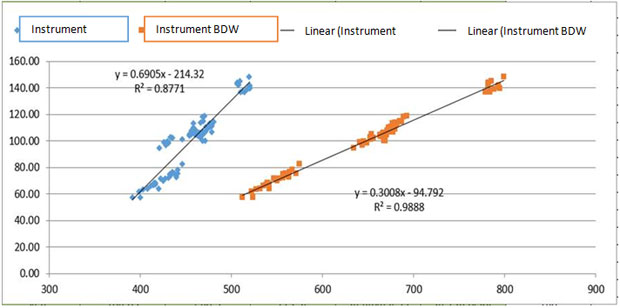

The microwave transducer produces a field that is several cm wide and several cm high. The exact location of wherein the field that the fabric and sheet matrix pass through the field, needed to be corrected. When this adjustment was made, subsequent measurements across numerous grade changes showed excellent correlation comparing sheet water content to total water content in the sheet and fabric (Figure 6). It is a straightforward conversion from water content in the sheet to consistency by removing the water content of the fabric.

Correlating Sheet Moisture to Total Moisture in the Fabric/Sheet Matrix

Figure 6 shows correlations between hand samples vs. instrument data.

Figure 6 shows correlations between hand samples vs. instrument data.

Author: Frank Cunnane, Product Specialist, Cristini North America inc.

Coauthor: Bernard Bigras-Denis, Product Manager-diagnostic systems, Cristini North America inc.

Source: Cristini